Switch to Using the Roland in Production Department Streamlines Processes and Creates High-Quality Graphics

For the past year, APH’s production department has been focusing on improving efficiency within the department. Thanks to the efforts of the entire team’s innovative thinking and use of new technology, the team has set the bar high for future achievements. One such way the team improved their capabilities was shifting from using the Green Machine to the Roland for printing tactile graphics for textbooks and other APH products. Recently, we spoke with Jane Thompson and Brian Sellers, along with several other members of the Production team about the reasoning behind the switch.

Used in the thermography printing process, the Green Machine, otherwise known as The Tactile Vision Process, is a piece of long equipment that is green and has the words ‘Green Machine’ along the side of it. Much like sending a document to print from your own computer, the thermography printing process requires that you send a graphic file to print from the wet ink printer.

Also called raised printing, the thermography process uses ink, plastic powders, and heat to create a raised image. The printers used in the process use ink that doesn’t immediately dry. While the ink is still wet, fine granules of powder are applied to it and then a vacuum is used to remove any powder that has not adhered to the ink. Once the excess powder is removed, the sheet is processed through a heat tunnel that melts the plastic powder. The whole process takes less than a minute. Then the graphic gets put into a textbook.

“It’s an old process. It worked great at the beginning, but over time things broke down. The process is breaking down, the product is breaking down. It’s not a good, useful graphic for our students, and therefore, we discontinued using it for textbooks, and now, I believe, everything,” says Jane Thompson, Director of Accessible Tests and Textbooks at APH.

“Due to technical issues with maintaining the equipment, ink formulation, and the quality of the output resulting from the equipment failure of the Green Machine and outdated processes, use of the Green Machine was no longer a viable option. As a result, the work from the Green Machine was assigned to four different tactile graphic production methods based on which one would provide the best results and value to APH and the customer,” says Brian Sellers, Maintenance Engineer on APH’s Production Team.

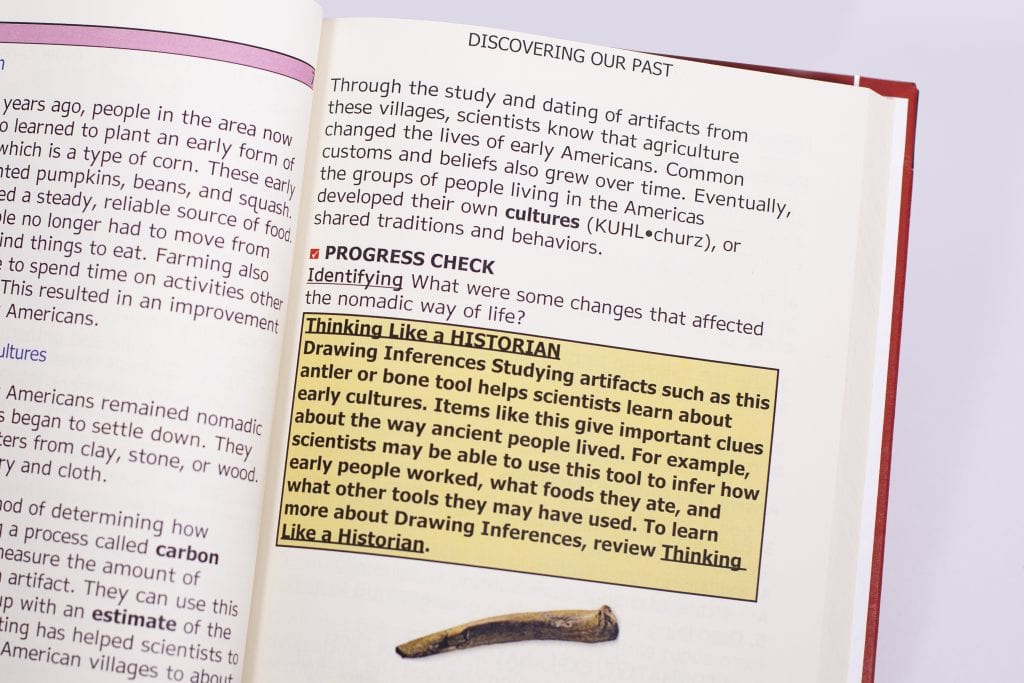

APH worked with vendors to find a more viable, long term printing option, the Roland models. A name brand of wide format inkjet printers, the Roland models utilize UV curable inks that allow APH to print multiple layers of ink, creating a durable raised image. The images are then used as masters to make thermoform copies of the original print. Those copies are then placed in textbooks, APH products, and tests. In addition to creating masters for the thermoforming process, durable raised graphics are printed directly onto plastics which are then processed and placed into our products. “Thermoforming with Roland masters produces excellent quality graphics. The process is ideal for products that require 100 or less copies per year, that have no print, and no requirements that the customers be able to mark the graphics with crayons or markers,” says Brian.

“The Roland graphic is a much higher quality graphic than the Green Machine ever was. The reason we previously ran certain graphics on the Roland process and other graphics on the Green Machine is because the Green Machine was really good for simple line drawings (ie. math diagrams, bar charts, Venn diagrams, etc.), whereas it was not a good process for a world map, water cycle, or something that had a lot of detail in it,” says Jane. “We used both processes strategically for the textbook it was designed for. Now, we only have one printer, which streamlines the process. Educationally, it’s a much more useful and user-friendly graphic for the reader, which is of utmost importance to APH.”

Share this article.

Related articles

Simplifying Standardized Tests with the Monarch

Standardized tests can be a source of anxiety for students who are blind or have low vision. Although they are...

Making Standardized Tests Accessible

What do you think of from October to April? Is it pumpkin spice, the holidays, Cyber Monday, basketball season, and...

About the APH Accessible Tests and Textbooks Department

To best serve our customers, the Accessible Tests and Textbooks Department offers a wide range of services. Accessible Tests: Extensive...